Eastern Refinery Limited

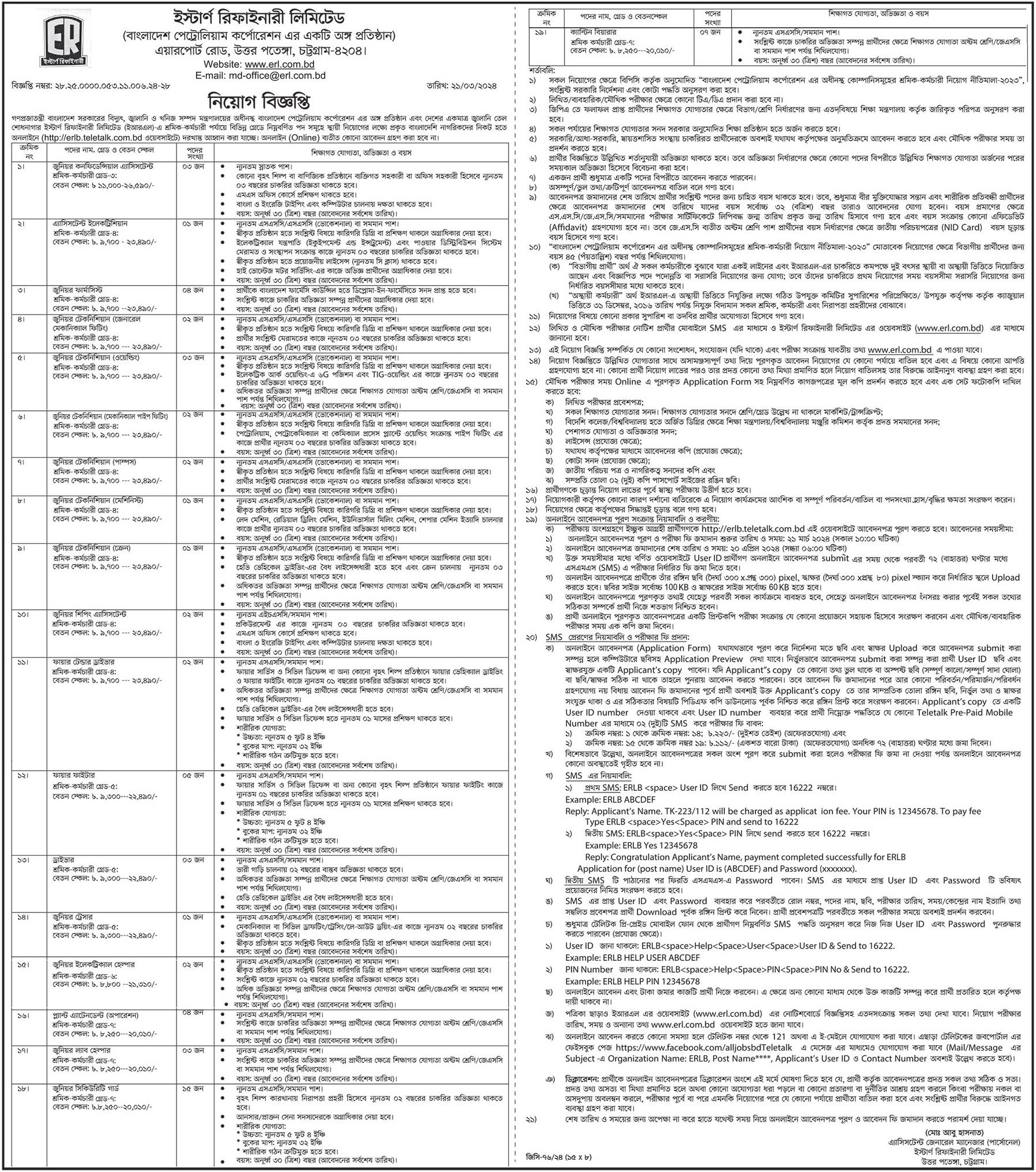

ইস্টার্ণ রিফাইনারী লিমিটেড

Job Category: Govt. Job

Job Source: বাংলাদেশ প্রতিদিন

Posted On: 21 Mar 2024

Application Deadline:20 Apr 2024

Wrb: www.eri.com.bd

Welcome to our website bangladeshtodays.org. This is the best website online. Here you will get daily updates on all types of job news such as: E.g Job Vacancies in Public Sector, Private Sector, Corporate, Banking, NGO Jobs etc. You can select any type of job from the category option in the top menu of the website. You can apply for jobs directly on our website. There is a search option at the top of this website where you can search for jobs according to your requirements. If you have benefited even in the slightest from our website, then you can tell your friends, family and everyone else about this website. I hope you also benefit from this website. You can share this website post on Facebook, Instagram, Twitter or any other online platform if you want. Many people can benefit from your sharing. And if there is anything you want to know or understand, you can contact us by email on the contact page of this website. We will try our best to help you, thank you very much.

**Introducing Eastern Refinery Limited (ERL):** Eastern Refinery Limited (ERL) is Bangladesh’s first oil refinery established to meet the growing demand for refined petroleum products in the country. Chittagong-based ERL plays an important role in refining crude oil into various petroleum products such as gasoline, diesel, kerosene and liquefied petroleum gas (LPG), thereby contributing to Bangladesh’s energy security and economic development. Contributing to **History and Establishment:** ERL was established in 1968 as a state-owned enterprise of the Bangladesh Petroleum Corporation (BPC) to address the country’s dependence on imported refined petroleum products. Construction of the refinery began in 1966 with technical assistance from the Soviet Union and became operational in 1975, with an initial refining capacity of 1.5 million tons per year. **Mission and Goals:** Eastern Refinery Limited’s mission is to ensure the supply of high-quality refined petroleum products to meet Bangladesh’s energy needs, promote self-reliance in the petroleum sector, and contribute to the country’s economic growth and development. The main purposes of ERL are: 1. **Refining Operations:** Refining crude oil into various petroleum products such as motor gasoline, diesel, kerosene, kerosene, and liquefied petroleum gas to meet the nation’s energy and transportation fuel needs. 2. **Quality Assurance:** We adhere to strict quality standards and ensure the production of safe, reliable and environmentally sustainable petroleum products that meet national and international specifications and regulatory requirements. 3. **Operational Efficiency:** Optimizing refinery operations involves maximizing production capacity and minimizing operating costs through efficient use of resources, technology upgrades, and process improvements. 4. **Safety and Environmental Compliance:** Adhering to the highest standards of safety, health and environmental protection in refinery operations in accordance with legal requirements and industry best practices to prevent accidents and reduce environmental impact. Reduce. 5. **Market Competitiveness:** By offering quality products at competitive prices, leveraging economies of scale, and adopting innovative marketing and sales strategies, we are able to dominate the national and regional oil markets. maintain competitiveness in **Purification process and equipment:** Eastern Refinery Limited’s refining process involves several stages including processing of crude oil, distillation, conversion of various fractions and refining into final petroleum products. Refinery equipment includes: 1. **Crude Distillation Unit (CDU):** CDU is the main processing unit in a refinery where crude oil is heated and separated into different fractions such as naphtha, kerosene, diesel, atmospheric residue etc. based on boiling point. will be separated into 2. **Fluid Catalytic Cracking (FCC) Unit:** FCC units convert heavy oil fractions into lighter and more valuable products such as gasoline and diesel through catalytic cracking reactions, thereby increasing the yield of high-octane fuels. increase the rate. 3. **Hydrodesulfurization Unit (HDS):** HDS units remove sulfur compounds from petroleum products such as diesel and gasoline to comply with environmental regulations and improve product quality and performance. 4. **Reformer:** The reformer converts low-octane naphtha into high-octane gasoline components such as aromatics and olefins through a catalytic reforming reaction, improving the octane number and knock resistance of gasoline. Masu. Five. **Hydrocracking Plants:** Hydrocracking plants process heavy oil fractions into lighter products such as diesel and kerosene through hydrogenation reactions, thereby improving product yield and quality. 6. **Utilities and Infrastructure:** ERL’s facilities include power generation, steam generation, water treatment, and product storage tanks to support refinery operations and meet the plant’s energy and water needs. Also includes public utilities. **Product Portfolio:** Eastern Refinery Limited produces a wide range of petroleum products to meet Bangladesh’s diverse energy needs. The refinery’s product portfolio includes: 1. **Motor Gasoline:** High-octane gasoline fuel for automobiles, motorcycles, and light trucks that meets performance and emissions standards set by regulatory agencies. 2. **Diesel:** High quality diesel fuel for trucks, buses, agricultural machinery and industrial equipment. Provides efficient and reliable energy for transportation and stationary applications. 3. **Kerosene:** A clean-burning kerosene used for lighting, cooking, and heating purposes, especially in rural areas where access to electricity and natural gas is limited. 4. **Jet Fuel:** Aviation turbine fuel for civil and military aircraft that meets international specifications and safety standards for flight operations. 5. **Stove oil:** A heavy fuel oil for industrial boilers, power plants, and ships that provides reliable, cost-effective energy for space heating and steam generation. 6. **Liquefied Petroleum Gas (LPG):** Bottled gas used for cooking, heating, and industrial applications, providing a clean and practical alternative to traditional fuels such as wood and charcoal. **Quality Control and Guarantee:** Eastern Refinery Limited maintains strict quality control and assurance measures to ensure the production of safe, reliable and environmentally sustainable petroleum products. The refinery’s quality control laboratory conducts regular testing and analysis of crude oil feedstock, intermediate products, and finished products to verify compliance with national and international standards, specifications, and regulatory requirements. ERL adheres to a rigorous quality management system, including ISO 9001 certification, and continually improves its processes, procedures and product quality. The refinery also works with regulators, independent auditors and industry partners to maintain the highest standards of quality, safety and environmental protection in its operations. **Environmental Responsibility:** Eastern Refinery Limited strives to minimize its environmental impact and reduce the impact of its operations on the environment and surrounding communities. Refineries implement a variety of environmental management practices and technologies to reduce air emissions, water pollution, solid waste generation, and noise levels.